Cambridge University researchers have developed a groundbreaking method to produce near zero-carbon cement by repurposing waste concrete. This innovative process involves utilizing cement paste extracted from crushed concrete as a substitute for lime in steel purification furnaces.

The byproduct of this process is a “reactivated cement” that can be effectively reused to create new concrete with comparable properties to the original material. This technique significantly reduces carbon emissions from both cement and steel production.

“Producing zero-emissions cement is a remarkable achievement,” emphasized Professor Julian Allwood, who led the research. “However, it’s equally crucial to minimize our overall consumption of cement and concrete.”

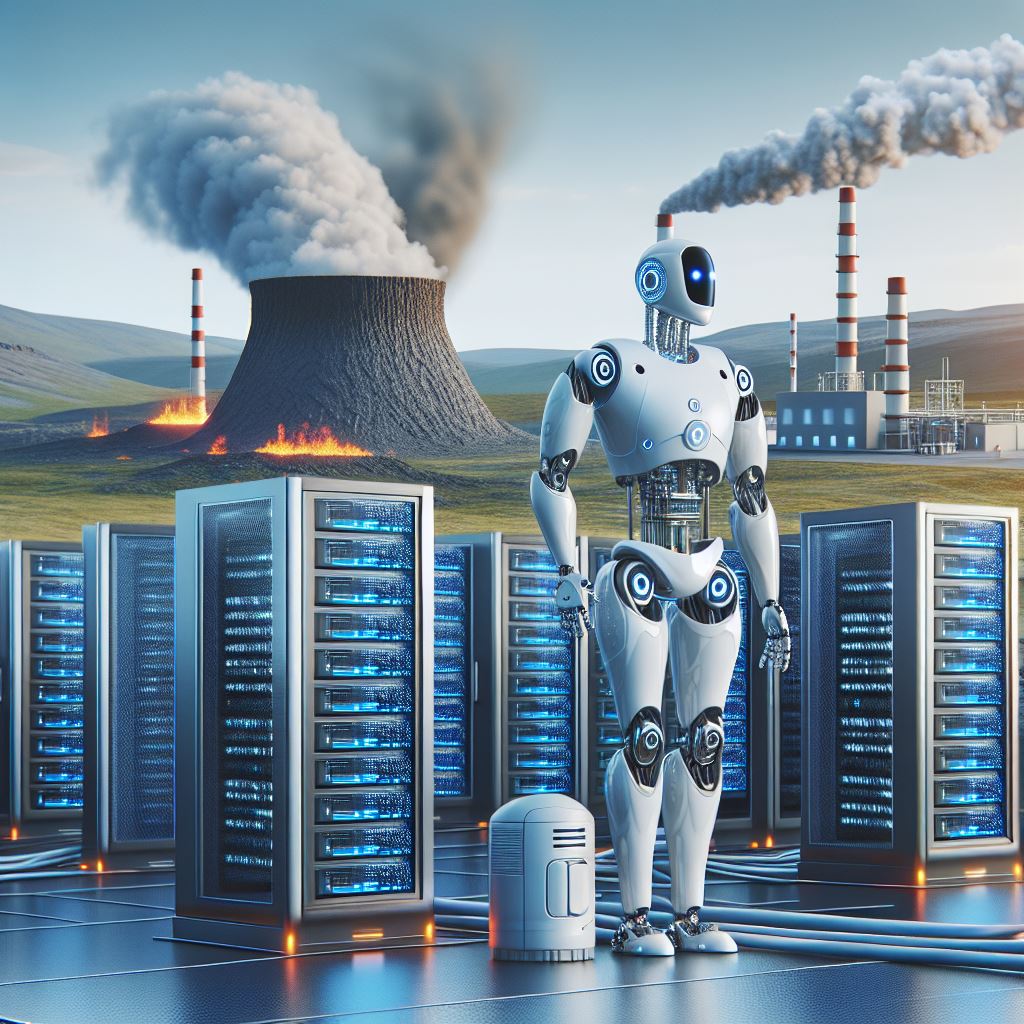

When powered by renewable energy sources, this method has the potential to achieve complete carbon neutrality. Initial trials have successfully demonstrated the feasibility of producing industrial quantities of this “electric cement.” Researchers are aiming for an ambitious target of producing one billion tonnes of this sustainable cement by 2050.

This breakthrough not only signifies a revolutionary advancement in the construction industry but also serves as a compelling example of how innovation can drive zero-emissions solutions across various sectors.

There are companies that are exploring making this more mass adoptable and we look forward to seeing these practices being standardized.